Dirt gathers around the wheel bearings, this combines with the old oil and wears away clock bearings. This is standard but neccessary work, overhauling every 5 – 10 years prevents this.

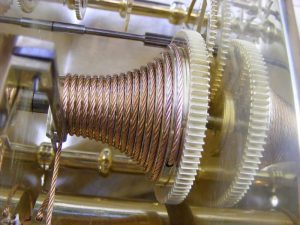

The old frayed line has stopped the clock. After (a new line is fitted as standard)

Re-grinding and polishing the pallet surfaces to remove wear improves timekeeping. Standard work for all restorations.

Before After

This English fusee clock before and after restoration…

Worn pivots can be replaced due to neglect…this one almost worn through!

Before After

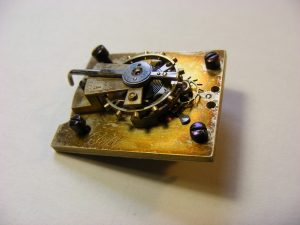

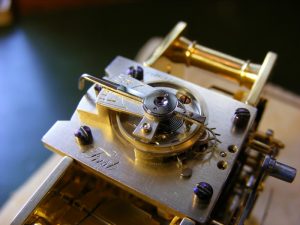

Dirty platform escapements clean up nicely on carriage clocks…

This crudely repaired hammer is a common site, it almost broke in my hand…After, newly silver soldered and finished as standard…